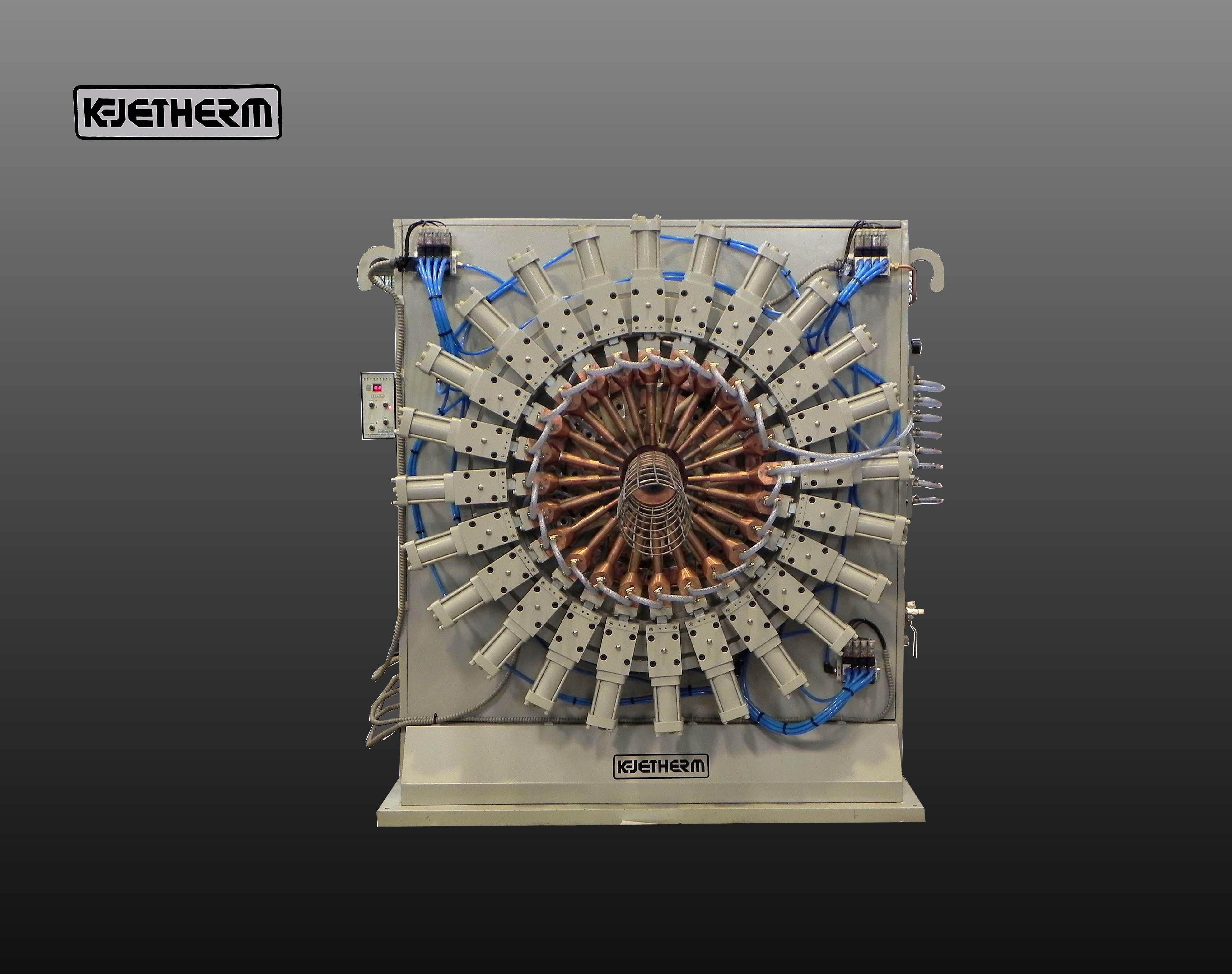

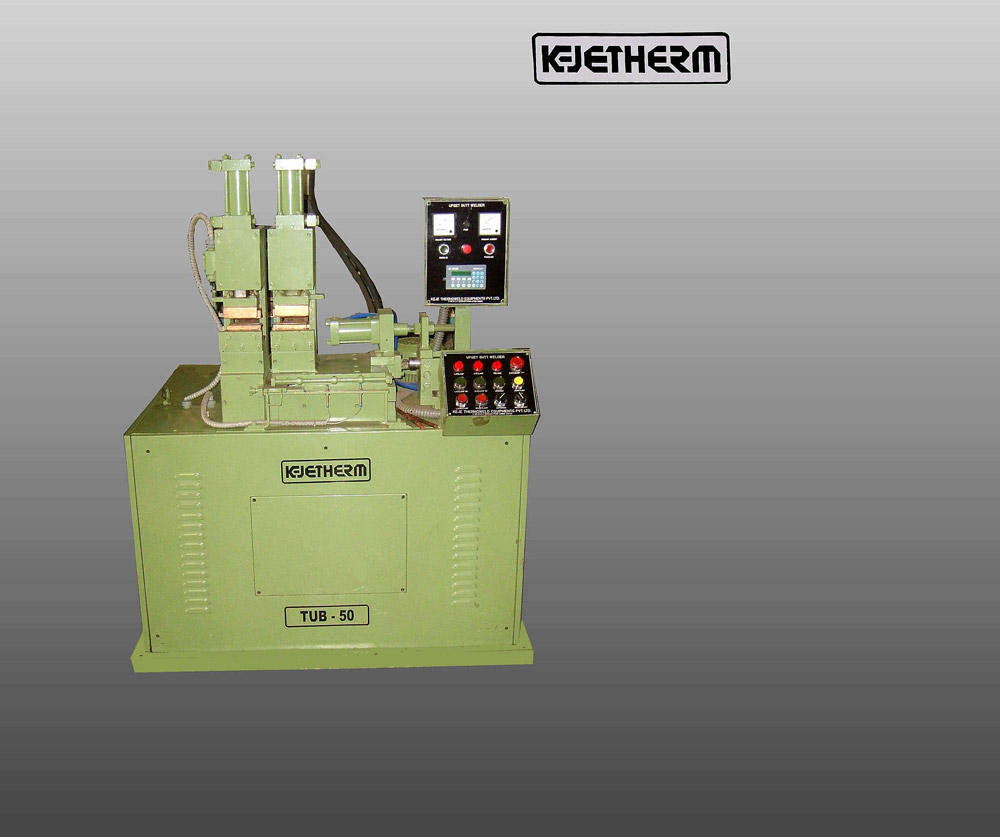

Spot Cum Projection Welder

SALIENT FEATURES

All operational controls - air, water and solid state electronic - are machine mounted, for easy access, safe and simple maintenance.

Weld sequence controller, sophisticated Quartz timer with squeeze, weld, hold and off timings with single/repeat cycle facility, weld timing being controlled by Thyristor circuit, heat controllable from 5% to 95%.

Electrode cushion control adjusts the descent of the upper electrode to any desired speed and completely eliminates 'hammer blow'.

Sturdy ram assembly permits high speed operation.